Factory Free sample Cnc Machine Lathe - CK6130S Slant Bed CNC Lathe Falco with 3 Axis – Falco

Factory Free sample Cnc Machine Lathe - CK6130S Slant Bed CNC Lathe Falco with 3 Axis – Falco Detail:

Product Features

The machine adopts lS0 international Code, Keyboard Manual Data Input, it is aso provided with program of power cut-off protection and the functions of automatic diagnosis, and with RS232 interface.

Longitudinal and cross feeds are effected by ball leadscrews driven by servo motors.

CK6130S: Either gang tool post or 4-way automatic tool post can be selected.

CK6140S: Either vertical or horizontal 4-stataion or 6-station tool post as well a gang tool can be selected.The pot is located on precision contrate gears with a high repeated positioning accuracy.

Both chuck and tailstock are supplied with hydranlic of manual or pneumatic type.

Infinitely variable speed change for spindle.

Both chuck and tailstock are available with hydraulic or manual or pneumatic type.

This machine is an economical CNC lathe controlled by a micro computer and driven by servo motors.It is suitable for tuning cylindrical and taper faces, boring, grooving and cutting threads.

Specifications

| Items | CK6130S | CK6136S | CK6140S |

| Max. swing over bed | φ300mm | φ360mm | φ410mm(16″) |

| Max.swing over slide | φ135mm/100mm(gang tools) | φ270/180mm(gang tools) | φ240mm/150mm(gang tools) |

| Max.cross travel(X) | 180/270mm(gang tools) | 230/300mm(gang tools) | 235/300mm(gang tools) |

| Max length of workpiece | 500mm | 500、750、1000mm | |

| Rapid feed for Axis X | 5m/min | ||

| Rapid feed for Axis Z | 8m/min | ||

| Range of spindle speeds(Stepless) | 200-3500r/min | 200-2800r/min | |

| Spindle bore | φ40mm | φ40mm | φ52mm |

| Taper bore of spindle | MT No.5 | MT No.6 | |

| 3-jaw chuck of collet | φ160 or 5c | φ200 or 5c | |

| Tool post | 4-way or 6-way or gang tools | ||

| Servomotor power(X/Z) | 0.75/1.0kW | ||

| Size of tool shank | 20x20mm | ||

| Min.input | 0.001mm | ||

| Repeatability(X/Z) | 0.0075/0.01mm | ||

| Surface roughness | ≤RaO.8μm(Nonferrous)≤Ra1.6μm(Steel part) | ||

| Main motor power | 3KW(4HP) | 3.7KW(5HP) | |

| Overall dimensions(L*W*H) | (1870,2120,2370)x1200x1415mm | ||

| Net weight | 950 | 170,020,002,200 | 180,021,002,300 |

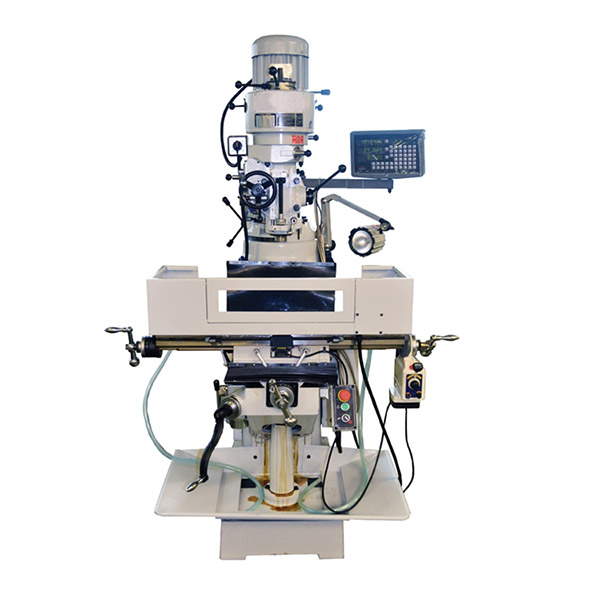

Product detail pictures:

Related Product Guide:

Our well-equipped facilities and great good quality regulate throughout all stages of manufacturing enables us to guarantee total buyer gratification for Factory Free sample Cnc Machine Lathe - CK6130S Slant Bed CNC Lathe Falco with 3 Axis – Falco , The product will supply to all over the world, such as: Nigeria, Jamaica, Bahrain, With the highest standards of product quality and service, our products have been exported to more than 25 countries like the USA, CANADA, GERMANY, FRANCE, UAE, Malaysia and so on.We are very pleased to serve customers from all over the world!

High production efficiency and good product quality, fast delivery and completed after-sale protection, a right choice, a best choice.