Factory making Double Column Machining Center - Frequency Conversion radial drilling machine Z3050X16/1 – Falco

Factory making Double Column Machining Center - Frequency Conversion radial drilling machine Z3050X16/1 – Falco Detail:

Product Description

The speed and feed of the machine tool have a wide range of speed changes, which can be operated by motor, manual and micro motion. The feed can be easily connected or cut off at any time. The feed safety mechanism is safe and reliable, and the clamping of each part is convenient and reliable; When the spindle is loosened and clamped, the displacement error is small. The variable speed control mechanism is concentrated on the spindle box, which is convenient for operation and speed change. The hydraulic power realizes the clamping of each part and the speed change of the spindle, which is sensitive and reliable.

The best batching process and pouring equipment are used for castings to ensure the high quality of the basic parts of the machine tool.

The main key parts are processed by imported machining center, with high precision and efficiency, which ensures the stable and reliable quality of the machine tool.

The parts of the spindle set are made of special high-quality steel and world-class heat treatment equipment to ensure high strength and wear resistance of the machine tool.

The main gears are ground to ensure high precision and low noise of the machine tool.

Specifications

| Model Item |

Unit |

Z3050×16/1

|

| Max drilling diameter |

mm |

50 |

| Distance between spindle axis and column (min/max) |

mm |

350/1600 |

| Distance between spindle axis and working surface of machine base (min/max) |

mm |

1220/320 |

| Rang of spindle speed |

r/mm |

25-2000 |

| Number of spindle speed |

No. |

16 |

| Rang of spindle feeds |

mm |

0.04-3.2 |

| Spindle taper(Mohs) |

No. |

5# |

| Number of spindle feeds |

No. |

16 |

| Spindle travel |

mm |

315 |

| Worktable dimensions |

mm |

630×500×500 |

| Horizontal |

mm |

1250 |

| Max torque of spindle |

500 |

|

| Power of main motor |

kW |

4 |

| Lifting distance of swing arm |

mm |

580 |

| Travel of slide block |

mm |

– |

| Weight of the machine |

kg |

3500 |

| Overall dimensions of the machine |

mm |

2500×1070×2840 |

Standard Accessories

Box worktable, taper handle socket, knife unloading wrench, knife iron and anchor bolt.

Special accessories (need to be purchased separately): quick change collet, tapping collet, oil gun.

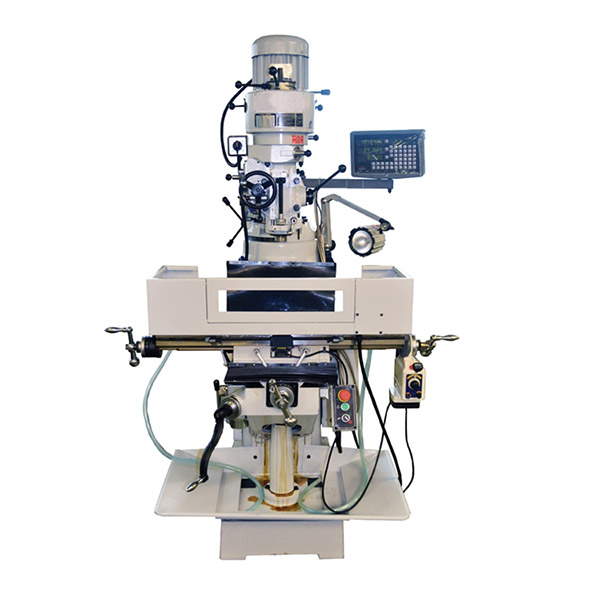

Product detail pictures:

Related Product Guide:

Our organization promises all customers with the first-class products and solutions and the most satisfying post-sale service. We warmly welcome our regular and new clients to join us for Factory making Double Column Machining Center - Frequency Conversion radial drilling machine Z3050X16/1 – Falco , The product will supply to all over the world, such as: South Korea, Curacao, Eindhoven, Our company offers the full range from pre-sales to after-sales service, from product development to audit the use of maintenance, based on strong technical strength, superior product performance, reasonable prices and perfect service, we'll continue to develop, to supply the high-quality goods and services, and promote lasting cooperation with our customers, common development and create a better future.

Goods just received, we are very satisfied, a very good supplier, hope to make persistent efforts to do better.