Factory Promotional Cnc Turning Machining Center – Frequency Conversion radial drilling machine Z3050X16/1 – Falco

Factory Promotional Cnc Turning Machining Center – Frequency Conversion radial drilling machine Z3050X16/1 – Falco Detail:

Product Description

The speed and feed of the machine tool have a wide range of speed changes, which can be operated by motor, manual and micro motion. The feed can be easily connected or cut off at any time. The feed safety mechanism is safe and reliable, and the clamping of each part is convenient and reliable; When the spindle is loosened and clamped, the displacement error is small. The variable speed control mechanism is concentrated on the spindle box, which is convenient for operation and speed change. The hydraulic power realizes the clamping of each part and the speed change of the spindle, which is sensitive and reliable.

The best batching process and pouring equipment are used for castings to ensure the high quality of the basic parts of the machine tool.

The main key parts are processed by imported machining center, with high precision and efficiency, which ensures the stable and reliable quality of the machine tool.

The parts of the spindle set are made of special high-quality steel and world-class heat treatment equipment to ensure high strength and wear resistance of the machine tool.

The main gears are ground to ensure high precision and low noise of the machine tool.

Specifications

| Model Item |

Unit |

Z3050×16/1

|

| Max drilling diameter |

mm |

50 |

| Distance between spindle axis and column (min/max) |

mm |

350/1600 |

| Distance between spindle axis and working surface of machine base (min/max) |

mm |

1220/320 |

| Rang of spindle speed |

r/mm |

25-2000 |

| Number of spindle speed |

No. |

16 |

| Rang of spindle feeds |

mm |

0.04-3.2 |

| Spindle taper(Mohs) |

No. |

5# |

| Number of spindle feeds |

No. |

16 |

| Spindle travel |

mm |

315 |

| Worktable dimensions |

mm |

630×500×500 |

| Horizontal |

mm |

1250 |

| Max torque of spindle |

500 |

|

| Power of main motor |

kW |

4 |

| Lifting distance of swing arm |

mm |

580 |

| Travel of slide block |

mm |

– |

| Weight of the machine |

kg |

3500 |

| Overall dimensions of the machine |

mm |

2500×1070×2840 |

Standard Accessories

Box worktable, taper handle socket, knife unloading wrench, knife iron and anchor bolt.

Special accessories (need to be purchased separately): quick change collet, tapping collet, oil gun.

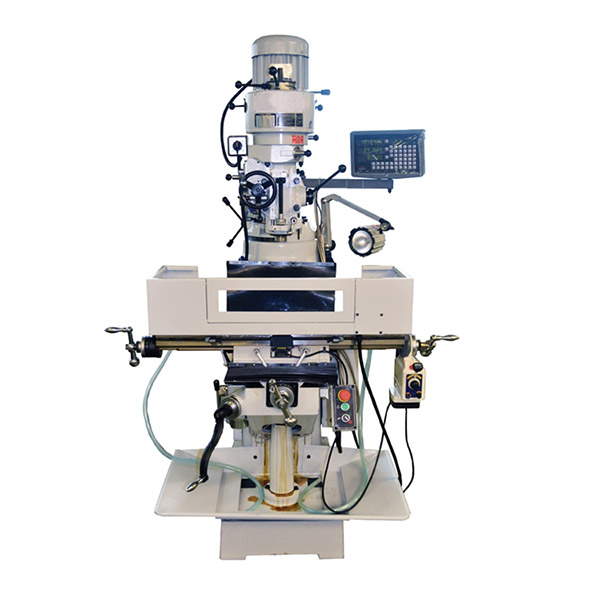

Product detail pictures:

Related Product Guide:

We support our purchasers with ideal premium quality products and substantial level company. Becoming the specialist manufacturer in this sector, we've acquired rich practical working experience in producing and managing for Factory Promotional Cnc Turning Machining Center – Frequency Conversion radial drilling machine Z3050X16/1 – Falco , The product will supply to all over the world, such as: Ottawa, Finland, Manchester, We have top engineers in these industries and an efficient team in the research. What is more, now we have our own archives mouths and markets in China at low cost. Therefore, we can meet different inquiries from different clients. Remember to find our website to check more information from our merchandise.

The customer service staff is very patient and has a positive and progressive attitude to our interest, so that we can have a comprehensive understanding of the product and finally we reached an agreement, thanks!