The integration of TF wear-resistant materials on vertical turret milling machines is revolutionizing manufacturing. This innovative material offers many benefits, from increased durability and reduced maintenance costs to improved cutting performance and increased precision. In this article, we explore the benefits of TF wear resistant materials and their impact on vertical turret milling machines.

TF wear resistant materials are designed to withstand the extreme wear typically associated with milling operations. By integrating this material into key components such as spindles, slides and bed, the durability and reliability of vertical turret milling machines are increased. Superior wear resistance reduces machine downtime and maintenance costs, ensuring manufacturers can maximize productivity.

The excellent hardness and toughness of TF wear-resistant materials significantly improve cutting performance. The material's ability to withstand high speeds and loads allows milling machines to run more efficiently and produce high-quality workpieces. Manufacturers can achieve higher cutting speeds, increase material removal rates and optimize their machining processes, ultimately increasing productivity and profitability.

The inherent stability and dimensional stability of TF wear-resistant materials contribute to precision and accuracy. It is capable of maintaining tight tolerances over long periods of use, ensuring consistent machining results. Even under heavy loads, the material resists deformation, allowing precise positioning and smooth movement. Manufacturers can rely on the exceptional precision of vertical turret milling machines to produce complex components with the highest precision.

TF wear-resistant materials can significantly extend the service life of cutting tools used in vertical turret milling machines. Its wear and abrasion resistance prevents premature tool failure, reducing the need for frequent tool changes. This not only improves efficiency, but also saves a lot of money. Manufacturers can optimize tool usage, minimize downtime and allocate resources more efficiently, improving overall profitability.

Integrating TF wear-resistant materials into vertical turret milling machines offers a range of benefits including increased durability, improved cutting performance and increased precision. With their ability to resist wear and maximize tool life, TF wear resistant materials are changing the face of milling machine technology.

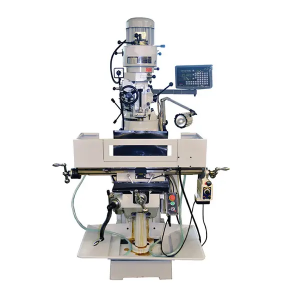

Our company, Falco Machinery,research and produce TM6325A vertical turret milling machine, with TF wearable material, which is the product deeply reflects the Benefits of TF wearable material for vertical turret milling machine. If you are interested in our company and our products, you can contact us.

Post time: Sep-06-2023