VMC850B CNC Milling machine, vertical machine center

Product Features

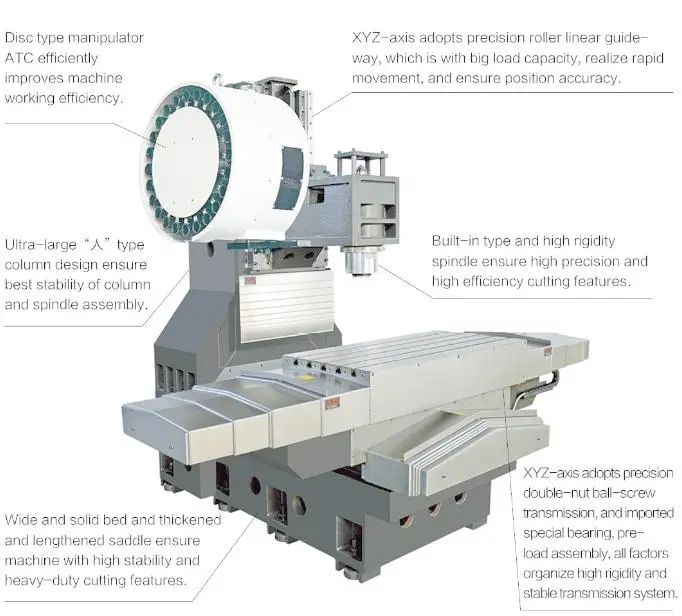

1.Overall instruction

This machine is designed with vertical frame layout. The column is mounted on the machine body, spindle box slides on the column forming Z axis motion, saddle slides on the machine body forming Y axis motion, Worktable slides on the saddle forming X axis motion. Three axes are all linear guideway with higher feed speed and higher precision. We use high quality gray cast iron for machine body, column, saddle, worktable, spindle box with resin sand technology and 2 times aging treatment to eliminate the internal residual stress of material. These parts are all optimized by SolidWorks software, which improves much the rigidity and stability not only for these parts but the machine. Also it will restrain the deformation and vibration caused by cutting. The important parts are all imported from world famous brand to make the machine with higher stability and durability. This machine can achieve the process of milling, drilling, reaming, boring, reaming, tapping and usually be used for Military, mining, automotive, mold, instrumentation and other mechanical processing industries. It can be used for all kinds of high precision and much process models. It is good for small and medium-sized, multi-variety production, also it can put into automatic production line.

2.Three axes system

Three axes are all linear guideway and with big span design for durable precision. The motors of 3 axes are connected directly with high precision ball screw by no gap flexible coupling. Each ball screw of 3 axes is imported from precision angular contacted ball screw and professional bearings matched, also we will do pre-tension for the ball screws for higher accuracy and precision.The Z-axis servo motor has an automatic brake function. In the case of power failure, the motor brake can be automatically held by the brake to prevent it from rotating, which plays a role in safety protection.

3.Spindle unit

Spindle is produced by professional manufacturer to make sure high precision and rigidity. Spindle bearing is from world famous high precision bearing brand, and assembled on the condition of constant temperature and no dust. After that , all spindles will do the test of dynamic balance to make sure the life span and reliability.It is equipped with low pressure air cycle protection system, blowing low pressure air into spindle inner space forming air protection layer to prevent dust,coolant into the spindle. For this condition, the spindle bearing will work under no pollution environment, which will protect the spindle unit and with longer spindle life span. Spindle speed can be no -step changed within the spindle speed range, which is controlled by motor inner encode to be with the function of spindle orientation and rigid tapping.

4.Tool change system

The standard tool magazine capacity of this machine is 24T and assembled on the side column. When it changes tool, tool plate drive and be positioned by motor drive hobbing cam mechanism, after the spindle arrive the position of tool change, the ATC will achieve the tool change and send tool action. ATC is hobbing cam mechanism and make pre-tension then can high speed rotation, which is better for quick and correct tool changing.

5.Coolant system

The machine is equipped with large flow upright immersion cooling pump and large capacity water tank. The cooling pump speed is 2m³/h to make sure ample recycle cooling. There is cooling nozzle on the spindle box end surface, which can make air coolant and water coolant for the tool and work pieces. Equipped with air gun to clean the machine and work pieces.

6.Pneumatic system

Pneumatic unit can filter the impurities and moisture in the gas source to avoid the damage and erosion of machine parts. Solenoid valve unit control the program by PLC to make sure the actions of spindle unclamping tool, spindle center blowing , spindle clamping tool and spindle air coolant can be made quickly and correctly. Every time spindle change tool, clear pressured air will blow from the spindle center to clean the spindle inner hole and tool shank for high rigidity of the combination with spindle and tool. It will expand the spindle life span.

7.Machine protection

We use standard safety protection shield for the machine , which can not only protect coolant splash but safety operation. Every guideway is equipped with protection shield to prevent the coolant and cutting piece into the inner space and lower the wearing and erosion of guideway and ball screw.

8.Lubrication system

Guideway and ball screw are equipped with central lubrication system and with volumetric oil separator in Each node, which can provide oil at fixed quantities and times to make sure each slide face lubricated and lower fabrication. It will improve accuracy and longer life span of ball screw and guideway.

9.Chip conveyor system

We provide standard manual chip remover device with easy operation. Also you can choose screw type chip conveyor or hinge type .

|

Item |

Unit |

VMC640L |

VMC640LH |

VMC850L |

VMC1000L |

|

Worktable |

|||||

|

Worktable size |

mm |

400×900 |

400×900 |

500×1000 |

500×1200 |

|

T-slot(N×W×D) |

mm |

3×18×100 |

3×18×100 |

5×18×100 |

5×18×100 |

|

Travel |

|||||

|

X axis travel |

mm |

640 |

640 |

850 |

1000 |

|

Y axis travel |

mm |

400 |

400 |

500 |

500 |

|

Z axis travel |

mm |

400 |

500 |

600 |

600 |

|

Machining range |

|||||

|

Distance from spindle center to column front |

mm |

440 |

476 |

572 |

572 |

|

Distance from spindle end to work table |

mm |

120-520 |

120-620 |

120-720 |

120-720 |

|

Machine dimension |

|||||

|

L×W×H |

mm |

2200×2100×2500 |

2200×2100×2550 |

2540×2320×2780 |

3080×2320×2780 |

|

Machine weight |

|||||

|

Max. load bearing of worktable |

kg |

350 |

350 |

500 |

600 |

|

Machine weight |

kg |

3900 |

4100 |

5200 |

5600 |

|

Spindle |

|||||

|

Spindle hole taper |

BT40 |

BT40 |

BT40 |

BT40 |

|

|

Spindle power |

kw |

5.5 |

5.5 |

7.5/11 |

7.5/11 |

|

Max. spindle speed |

rpm |

8000/10000 |

8000/10000 |

8000/10000 |

8000/10000 |

|

Feed(direct drive) |

|||||

|

Max. feed speed |

Mm/min |

10000 |

12000 |

12000 |

12000 |

|

Rapid feed speed (X/Y/Z) |

m/min |

20/20/10 |

30/30/24 |

32/32/30 |

32/32/30 |

|

Ball screw (diameter + lead) |

|||||

|

X axis ball screw |

3210 |

3212 |

4016 |

4016 |

|

|

Y axis ball screw |

3210 |

3212 |

4016 |

4016 |

|

|

Z axis ball screw |

3210 |

4012 |

4016 |

4016 |

|

|

Tool Magazine |

|||||

|

Tool magazine capacity |

T |

16 |

16 |

24 |

24 |

|

Tool change time |

s |

2.5 |

2.5 |

2.5 |

2.5 |

|

Positioning accuracy (National standard) |

|||||

|

Positioning accuracy (X/Y/Z) |

mm |

0.008 |

0.008 |

0.008 |

0.008 |

|

Re-positioning accuracy(X/Y/Z) |

mm |

0.005 |

0.005 |

0.005 |

0.005 |

| NO. | Name | Brand |

| 1 | CNC system | Seimens 808D SYSTEM |

| 2 | Main motor | Full set of Siemens drive including servo motor |

| 3 | X/Y/Z axis motor, driver | Seimens |

| 4 | Ballscrew | Hiwin or PMI (Taiwan) |

| 5 | Ballscrew bearing | NSK (Japan) |

| 6 | Linear guides | Hiwin or PMI (Taiwan) |

| 7 | Spindle motor | POSA/ROYAL (Taiwan) |

| 8 | Heat exchanger | Taipin/Tongfei (Joint-venture) |

| 9 | Lubrication system main components | Proton (Joint venture) |

| 10 | Pneumatic system main components | AirTAC (Taiwan) |

| 11 | Electric system main components | Schneider (France) |

| 12 | Water pump | China |